When most people think about roofing or spill control, they usually think in terms of coverage. Will it leak? Will it last through the storm? But what often gets missed in that calculation is the structural logic behind both systems. Whether you’re working with a flat roof in a city or managing spill containment in an industrial zone, you’re dealing with surfaces that have to hold back pressure, temperature shifts, and moisture. The logic remains the same—even if the applications differ.

A Shared Foundation of Durability

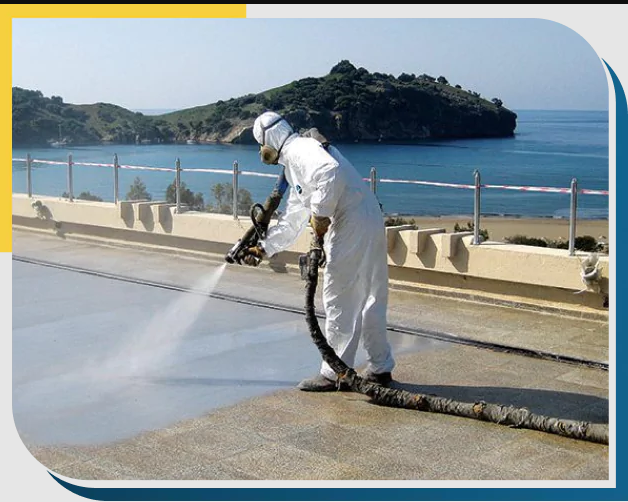

Buildings survive when their uppermost and lowermost surfaces hold up under stress. You can’t underestimate the role of material science in that equation. Polyurea, a fast-setting and highly elastic coating, has been showing up more often in both fields. In roofing, it creates a watertight layer that resists pooling, UV degradation, and aging. In containment, it prevents chemicals and waste from seeping into soils and groundwater. What gives polyurea this flexibility is its reaction chemistry, which doesn’t just coat the surface—it bonds with it.

If you’ve ever studied the behavior of flat roofs, particularly in areas where temperature fluctuations stress every seam and edge, you’ll understand why this matters. Expansion and contraction pull at the edges of the structure day after day. Over time, even the smallest cracks invite failure. You can explore how this plays out in detail by reading how polyurea handles thermal movement on flat roofs. That same movement happens around containment barriers, too, especially when chemical spills heat up or cool down a surface rapidly.

Surface Integrity and What It Prevents

You don’t need a roof to understand water movement. Any surface left unprotected will eventually allow penetration. This is why industrial zones and construction firms have started applying flat roof techniques to ground-level containment. The core idea lies in protecting the surface not just with mass, but with chemistry—specifically, a seamless membrane that allows no weak points.

When applied to a spill containment area, these seamless membranes reduce the risk of leaching. This not only protects the soil but also the water table beneath it. The best protection happens when you consider not only the material spilled but the substrate it could enter. Concrete alone may resist moisture, but it doesn’t stop aggressive chemicals from making their way through. That’s where coating technologies step in.

ArmorThane has become one of the more recognized players in this area, offering solutions that reflect a shift in how industries view containment zones. Instead of a physical wall alone, many are now choosing to reinforce their sites with flat roof waterproofing products that mimic the behavior of successful commercial roof systems. The result has been a stronger line of defense.

The Seam That Holds the System Together

If you zoom in on a failure—whether on a roof or a barrier—you almost always find it starts at a seam. A small break becomes a path, and from that path spreads weakness. So when engineers began designing coatings that could remove the concept of seams entirely, they effectively changed the conversation. A seamless flat roof coating does more than eliminate points of entry—it gives the whole surface uniformity.

That uniformity becomes even more valuable when it is combined with speed. One of polyurea’s core strengths lies in how fast it can cure. In minutes, a full layer of protection sets into place. This matters in containment areas where operations can’t afford long delays. Cleanup and control must happen fast, and reapplication should not hold up progress. Roofing systems, with their weather limitations and scheduling demands, faced that same challenge—and polyurea provided an answer.

Looking Below for Better Outcomes Above

As cities expand and infrastructure ages, both roofs and ground-level systems face pressure to perform beyond their original expectations. New materials offer an answer, but only if applied with attention to detail and long-term impact. Containment has to stop thinking of itself as a reactive discipline. The same shift has already happened in roofing, where prevention now plays a central role. You seal before the leak. You fortify before the rain.

With spill containment, that philosophy is gaining traction. Contractors, site managers, and engineers have begun integrating waterproofing strategies developed for commercial buildings into the way they secure their work zones. It makes sense. When water or chemical infiltration can lead to legal consequences, environmental damage, and costly repairs, the cost of protection always looks smaller in comparison.

Conclusion

Flat roof waterproofing and containment zones might seem like two very different problems, but the way we solve them increasingly points to the same set of technologies. Polyurea has created a bridge between those worlds by offering a method that doesn’t just coat—it seals, strengthens, and adapts. As the demands on infrastructure grow more complex, the smartest solutions will be the ones that already understand how everything connects—from roof to ground.